Have you noticed your circular saw blade struggling to slice through wood like it once did? A dull blade can turn even the simplest tasks into frustrating chores, slowing you down and affecting the quality of your work.

But before you rush to buy a new blade, consider sharpening it yourself. Not only is it cost-effective, but it also prolongs the lifespan of your equipment. Imagine gliding through your projects with ease and precision, just like when your blade was brand new.

In this guide, you’ll discover straightforward steps to sharpen your circular saw blade, helping you reclaim the efficiency and sharpness you need for your projects. Keep reading to unlock the secret to maintaining your tools and enhancing your craftsmanship.

Credit: www.youtube.com

Understanding Circular Saw Blades

Understanding circular saw blades is crucial for anyone who wants to maintain their tools and ensure optimal performance. You might not think much about the blade itself, but knowing its details can make all the difference in your cutting projects. Let’s explore what makes these blades tick and how you can keep them sharp.

Types Of Blades

Circular saw blades come in various types, each suited for specific tasks. If you’ve ever been in a hardware store, you might have seen blades labeled for cutting wood, metal, or masonry. Wood-cutting blades are the most common, often featuring carbide tips for durability. Metal-cutting blades are typically made of stainless steel, designed to slice through metals without breaking a sweat. Masonry blades, on the other hand, are crafted with diamond edges to tackle tough materials like concrete.

Choosing the right blade type can significantly affect your project’s outcome. Imagine trying to cut metal with a wood blade; the results could be disastrous. Have you ever used the wrong type of blade and realized how much more effort you had to exert? That’s why matching the blade to the task is essential.

Common Materials Used

The material of a circular saw blade is as important as its type. Most blades are made from high-speed steel or carbide. High-speed steel blades are durable and inexpensive, making them a popular choice for general-purpose cutting. However, they can dull quickly when used on harder materials.

Carbide blades, on the other hand, offer greater longevity and remain sharp for longer periods. They are ideal for heavy-duty jobs but come at a higher price. Think of carbide blades as the premium option—they save you time in the long run because you won’t need to sharpen them as often.

Have you ever used a blade that wore out faster than expected? Understanding the material helps prevent such situations. Picking the right material can save you both time and money.

As you ponder over these details, ask yourself: How well do you know your tools? Investing a bit of time in understanding your circular saw blades can lead to better cuts and fewer headaches. It’s not just about keeping them sharp but ensuring you have the right blade for the job. Next time you pick up your saw, remember these insights and make your cutting projects smoother and more efficient.

Credit: www.youtube.com

Signs Your Blade Needs Sharpening

Maintaining a sharp circular saw blade is essential for efficient cutting. A dull blade can be frustrating and dangerous. Knowing the signs of a dull blade helps you maintain safety and efficiency. Let’s explore the common signs.

Performance Issues

Notice a decrease in cutting speed? This could mean a dull blade. A sharp blade cuts smoothly, with minimal resistance. Struggling with the saw? It’s time for sharpening. Also, listen for unusual sounds. A dull blade often makes a high-pitched noise. These are all signs of performance issues.

Visible Wear And Tear

Inspect the blade for visible damage. Look for chipped or missing teeth. These indicate a need for sharpening. A sharp blade will have clean, intact teeth. Check for a shiny or burnt appearance. This suggests friction due to dullness. Routine inspection can prevent accidents.

Essential Tools For Sharpening

Sharpening a circular saw blade can seem daunting, but with the right tools, it’s a task you can tackle efficiently. Having the proper tools not only speeds up the process but also ensures accuracy and safety. Imagine the satisfaction of cutting through wood like butter after sharpening your blade with precision.

Sharpening Devices

To sharpen a circular saw blade, you’ll need a few essential devices. A diamond file is perfect for manually honing the teeth of the blade, offering precision. If you prefer automation, a blade sharpening machine can save time and provide consistent results.

Consider investing in a saw blade sharpener with adjustable settings. This allows you to customize the sharpening angle based on the type of blade you have. A rotary tool with a grinding disc attachment can also be a handy companion for quick touch-ups.

Have you ever tried sharpening with a homemade jig? It can be a fun project, giving you control over the blade’s sharpness. However, ensure your jig is sturdy and can hold the blade securely.

Safety Gear Required

Safety should be your top priority when sharpening saw blades. Eye protection is crucial to shield your eyes from flying metal shards. Dust masks help prevent inhalation of metal particles, keeping your lungs healthy.

Wearing gloves can protect your hands from accidental cuts. However, ensure they fit well, as loose gloves might get caught in machinery. Consider using ear protection if you opt for electric sharpening devices, reducing noise exposure.

Would you risk your safety by ignoring these essentials? A little preparation goes a long way in preventing accidents and ensuring a smooth sharpening process.

Preparing The Blade For Sharpening

Begin by ensuring the circular saw blade is clean and free from any debris or rust. Carefully remove the blade from the saw, securing it safely for the sharpening process. This preparation step is crucial for achieving a sharp, efficient cutting edge.

Preparing a circular saw blade for sharpening is essential. A well-prepared blade ensures a smooth sharpening process. It also prolongs the lifespan of your tool. Cleaning and securing the blade are crucial first steps. These steps are simple yet vital for effective sharpening.

Cleaning The Blade

Begin by removing any dust and debris. A clean blade improves sharpening accuracy. Use a brush or cloth to wipe the blade’s surface. For stubborn grime, a mild detergent can help. Soak the blade briefly, then scrub gently. Rinse and dry it completely before proceeding. This prevents rust and ensures a clear view of the teeth.

Securing The Blade

Properly securing the blade is crucial for safety. Place the blade on a stable workbench. Use clamps to hold it firmly in place. This prevents any movement during sharpening. Check the blade’s stability before starting. A secured blade avoids accidents and ensures precision.

Step-by-step Sharpening Guide

Sharpening a circular saw blade improves its efficiency and extends its lifespan. Start by gathering necessary tools like a diamond file and safety gear. Carefully follow each step to ensure precise sharpening for optimal cutting performance.

Sharpening a circular saw blade might seem daunting, but it’s a skill that can save you money and improve your tool’s performance. With a few straightforward steps, you can breathe new life into your saw blade. Whether you’re a DIY enthusiast or a seasoned woodworker, understanding how to sharpen your blade ensures smoother cuts and extends the blade’s lifespan. Let’s dive into the step-by-step guide to make your blade as sharp as ever.

Setting Up The Equipment

Before you start, gather your tools. You’ll need a sharpening file, a bench vise, and safety gear like goggles and gloves. Secure the circular saw blade firmly in the bench vise. This ensures stability and precision during sharpening. Check the blade for any signs of damage or excessive wear. If the teeth are chipped or broken, consider replacing the blade instead.

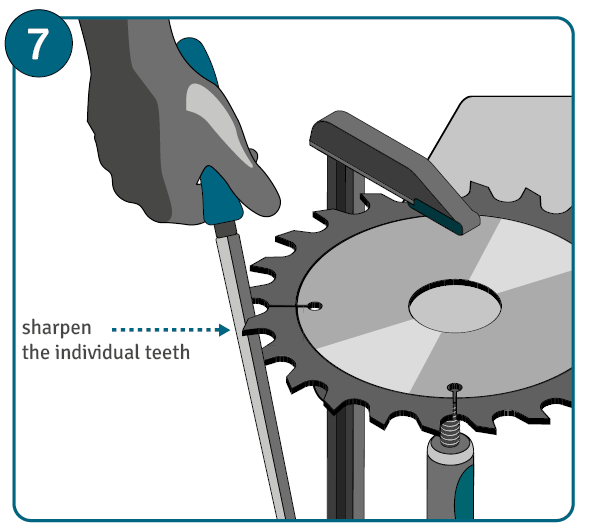

Sharpening Techniques

Begin sharpening with a consistent motion using your file. Keep the angle steady to maintain uniform sharpness across all teeth. Count the number of strokes you apply to each tooth. Consistency is key to achieving a balanced blade. Rotate the blade and repeat the process for each tooth. This methodical approach ensures every part of the blade gets the attention it needs.

Checking The Blade’s Balance

After sharpening, check if the blade is balanced. An imbalanced blade can lead to uneven cuts and potential safety hazards. Place the blade on a flat surface and observe its movement. If it tips to one side, additional adjustments may be necessary. Ask yourself, how does your saw feel when you use it? A well-balanced blade should move smoothly without vibration. Ensuring your circular saw blade is sharp and balanced not only improves your project outcomes but also enhances your safety. By following these steps, you empower yourself to maintain your tools effectively. Are you ready to experience the difference a sharp blade makes in your woodworking?

Maintaining The Sharpness

Sharpening a circular saw blade keeps cuts smooth and fast. Use a file or a dedicated sharpening tool. Regular maintenance saves time and extends the blade’s life, ensuring efficient performance.

Maintaining the sharpness of your circular saw blade ensures smooth cuts. It also extends the life of your tool. Regular care prevents dullness and keeps efficiency high. This guide will help you keep your saw blade sharp and ready.

Regular Maintenance Tips

Clean your blade after each use. Dust and resin build-up dulls the blade. Use a soft brush to remove debris. Inspect the blade regularly. Check for nicks or worn teeth. Replace damaged blades immediately. Lubricate the blade occasionally. This reduces friction during use. Avoid using too much oil. A light coat is enough to protect.

Proper Storage Practices

Store the blade in a dry place. Moisture causes rust and dulling. Hang the blade on a wall peg or store it flat. Avoid stacking blades on top of each other. Cover the blade with a protective case. This prevents accidental damage. Keep the blade away from children and pets. Safe storage prolongs blade life.

Common Mistakes To Avoid

Avoid applying too much pressure when sharpening circular saw blades. Using inappropriate tools can damage the blade. Ensure proper angle and technique to maintain cutting efficiency.

Sharpening a circular saw blade is a critical task that can extend the life of your tool and ensure precision in your woodworking projects. However, many people make mistakes that can lead to poor performance or even damage to the blade. Knowing what to avoid can save you time, money, and frustration. Let’s dive into some common mistakes to avoid when sharpening your circular saw blade.

Over-sharpening

Over-sharpening is a trap many fall into, thinking that sharper is always better. While a sharp blade is crucial, going overboard can wear out the blade faster. Imagine spending hours meticulously sharpening only to find the teeth breaking off during your next project. It’s a nightmare! The key is to sharpen just enough to restore the blade’s edge without compromising its structural integrity. Have you ever noticed that over-sharpening doesn’t necessarily improve cutting performance? It’s like trying to drink from a fire hose. Instead, aim for a balanced sharpness that maintains the blade’s longevity while providing clean cuts.

Ignoring Safety Measures

Safety should be your top priority when working with sharp tools. Ignoring safety measures can lead to serious injuries, not to mention a ruined blade. Before you begin, ensure you have the necessary protective gear, like gloves and safety goggles. It’s easy to get caught up in the task, but these precautions are your first line of defense against accidents. Think back to the last time you accidentally nicked yourself while sharpening. A small oversight can result in a painful reminder of the importance of safety. Always unplug the saw before starting and secure the blade properly to avoid mishaps. Are you overlooking any safety measures in your sharpening routine? Double-checking might save you from a trip to the emergency room. Remember, sharpening your skills should never come at the cost of your safety.

When To Replace Your Blade

Replacing a circular saw blade depends on its sharpness. Dull blades struggle to cut smoothly. Frequent sharpening can extend its life, but eventually, replacements ensure optimal performance and safety. Regular checks help decide the right time for a new blade.

When it comes to maintaining your circular saw, knowing when to replace the blade is crucial. A dull or damaged blade can hinder your projects and compromise safety. While sharpening can extend its life, there comes a point when replacing the blade is the smarter choice. Let’s delve into the signs that indicate a blade replacement is necessary and the considerations that go into making that decision.

Assessing Blade Condition

Inspect your blade regularly for visible damage. Look for chipped or missing teeth. If you notice burnt wood edges or increased resistance, these are signs of a worn-out blade. Listen to the saw while cutting; strange noises can indicate internal blade issues. Consider your cutting materials. Softer woods wear blades differently than harder materials. If you frequently cut through nails or screws, your blade may degrade faster. These factors can guide your assessment of the blade’s condition.

Cost Vs. Benefit Analysis

Replacing a blade involves cost, but it also offers benefits. Compare the price of a new blade to the time and effort required to sharpen an existing one. If sharpening doesn’t restore performance, replacement might be more cost-effective. Think about your projects. A sharp blade ensures precision and speed, saving you time and improving results. Investing in a new blade can be worthwhile if it enhances your overall work efficiency. Does your saw blade affect your productivity? Weigh the convenience of a new blade against sharpening costs. A dull blade might cost you more in wasted materials and time. Consider long-term benefits when making your decision. Ultimately, the decision to replace your blade should balance cost with performance. A fresh blade can rejuvenate your saw and elevate your projects.

Credit: smallboatsmonthly.com

Frequently Asked Questions

Is It Worth Sharpening Circular Saw Blades?

Sharpening circular saw blades can save money and improve cutting performance. Dull blades lead to rough cuts and increased effort. Regular sharpening ensures precise cuts, prolongs blade life, and enhances efficiency. Consider professional sharpening for best results. Investing time in maintenance maximizes tool longevity and effectiveness.

Does Ace Hardware Sharpen Saw Blades?

Ace Hardware stores often offer saw blade sharpening services. Availability varies by location, so check with your local store. This service helps maintain blade efficiency and prolongs its lifespan. It’s advisable to contact your nearby Ace Hardware to confirm if they provide saw blade sharpening services.

How Do You Sharpen A Saw Blade By Hand?

To sharpen a saw blade by hand, use a triangular file. Secure the saw in a vice. File each tooth’s edge in the correct direction. Maintain consistent angles. Finish by smoothing with a sharpening stone.

Is It Better To Sharpen Saw Blades Or Buy New?

Sharpening saw blades is often cost-effective and extends their lifespan. New blades can be expensive, especially for specialized tools. Regular sharpening maintains performance, saving you money over time. Assess blade condition and usage frequency to decide. Buying new is better for severely damaged blades.

Conclusion

Sharpening your circular saw blade can boost its performance and lifespan. Follow the steps carefully to ensure safety and precision. Use the right tools for best results. Remember to check your blade’s condition regularly. Clean and maintain it for smooth operation.

Avoid rushing the sharpening process. Take your time to do it right. A sharp blade cuts faster and cleaner. It also reduces wear on your saw. By maintaining your blade, you save money and time. Happy cutting!