Are you ready to unlock the full potential of your impact wrench? Whether you’re a seasoned DIY enthusiast or just getting started with power tools, knowing how to properly attach a socket to your impact wrench is a game-changer.

Imagine the satisfaction of effortlessly tackling tough jobs and speeding up your projects. But here’s the catch: if you don’t do it right, you could end up with a tool that doesn’t work as efficiently or even risk damaging your equipment.

That’s why mastering this simple yet crucial step can make all the difference in your tool’s performance and your project’s success. Keep reading to discover the secrets to securely attaching a socket to your impact wrench and take your tool game to the next level!

Credit: www.familyhandyman.com

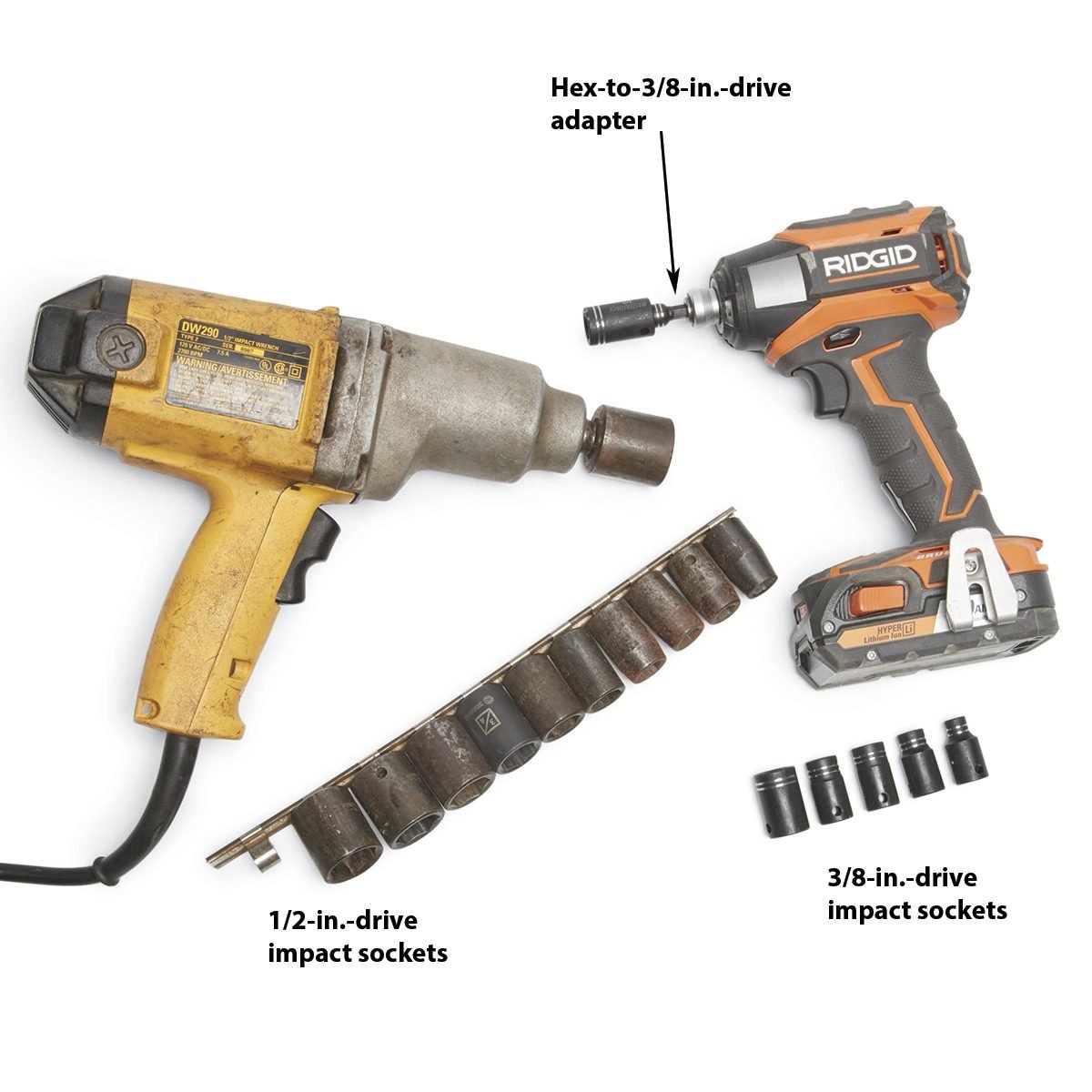

Choosing The Right Socket

Choosing the right socket for your impact wrench is crucial. It ensures efficient performance and safety. Different tasks need different sockets. Picking the wrong one can damage tools or projects. Understanding the differences helps in making the right choice. This section covers key considerations.

Impact Vs. Standard Sockets

Impact sockets are designed for high-torque applications. They are usually black and thicker. They handle the force of an impact wrench without breaking. Standard sockets are thinner and often chrome. They are for manual use. Using them with impact wrenches can be dangerous. The force can cause breakage or injury.

Material And Size Considerations

Impact sockets are usually made from chrome molybdenum. This material is tough and durable. It withstands high pressure. Standard sockets are often chrome vanadium. They are less durable under high impact. Size is also critical. Ensure the socket fits your wrench and fastener. A loose fit can strip the bolt. A tight fit can damage the socket or wrench.

Preparing The Impact Wrench

Before using an impact wrench, proper preparation is essential. This ensures safety and efficiency. Follow these steps for a smooth operation.

Inspecting The Tool

Check the impact wrench for visible damage. Ensure all parts are intact. Look for cracks or loose components. A damaged tool can be dangerous. Verify the power source connection. Whether electric or air-powered, connections must be secure.

Safety Measures And Precautions

Wear safety goggles to protect your eyes. Gloves can shield your hands from injuries. Ensure the area around you is clear. Loose objects can cause accidents. Keep your work area well-lit. Good visibility reduces the risk of mistakes.

Secure your workpiece before starting. An unsecured piece can move unexpectedly. Read the manufacturer’s instructions carefully. Each tool may have unique guidelines. Familiarize yourself with the controls and settings. Knowing your tool is crucial for safe use.

Attaching The Socket

Attaching a socket to an impact wrench is a straightforward process. Proper alignment and secure connection are crucial for effective tool use. This ensures safety and efficiency during operation.

Aligning The Socket

First, identify the correct socket size for the task. This prevents damage and ensures accuracy. Place the socket onto the impact wrench’s square drive. Align the socket’s hole with the wrench’s drive head. This step requires attention to detail. Make sure the socket fits snugly.

Securing The Connection

Once aligned, push the socket firmly onto the drive head. Listen for a click or feel for a snap. This indicates a secure connection. Check the socket’s stability by gently twisting it. The socket should not wobble or fall off. Ensure it is locked in place before using the wrench.

Credit: www.youtube.com

Testing For Proper Fit

Ensure the socket aligns with the impact wrench’s anvil for a secure fit. Press firmly until it clicks into place. Test by gently pulling to confirm it’s secure before use.

Testing for proper fit is crucial when attaching a socket to an impact wrench. It ensures the socket remains secure during use. A poor fit can lead to damage or accidents. This section will guide you on how to test the fit effectively.

Checking For Tightness

First, slide the socket onto the impact wrench. It should fit snugly without force. Once in place, gently pull the socket to test its grip. It should not slide off easily. A tight fit ensures the socket stays secure during operation. Loose sockets can lead to inefficiency or damage. Always check for tightness before starting any task.

Ensuring Socket Stability

Next, assess the socket’s stability. Rotate the socket slightly while attached to the wrench. It should move smoothly without wobbling. A stable socket maintains consistent torque. Instability can affect the tool’s performance. Listen for any unusual sounds during rotation. Any noise might indicate a poor fit. Always prioritize stability for effective and safe tool use.

Common Mistakes To Avoid

Impact wrenches are powerful tools. They simplify tasks like loosening tough bolts. But improper use can lead to damage or injury. Avoid common mistakes to keep your tool and yourself safe. Here’s how you can do it.

Using Incorrect Sizes

Always check socket sizes before use. Using the wrong size can strip bolts. It might damage the tool too. The socket must fit snugly over the nut or bolt. Loose sockets slip and cause accidents. Ensure the socket matches the bolt size perfectly.

Ignoring Safety Protocols

Safety is crucial when using impact wrenches. Wear protective gear like gloves and goggles. These protect against flying debris. Keep your fingers away from moving parts. Never rush while handling power tools. A calm approach prevents accidents. Follow safety guidelines for a smooth operation.

Credit: www.familyhandyman.com

Maintenance Tips

Maintaining your impact wrench and socket ensures their longevity and efficiency. Regular care prevents damage and ensures safe operation. Follow these tips to keep your tools in top shape.

Cleaning The Socket And Wrench

After each use, clean your socket and wrench with a soft cloth. Remove any dirt or debris that could cause wear. Pay attention to the socket’s inside to ensure it’s free of residue.

Use mild soap and water for stubborn grime. Ensure all parts are dry before storing them. Moisture can lead to rust and other damage.

Storing Tools Properly

Store your tools in a dry, safe place. Use a tool box or case to prevent exposure to dust and moisture.

Organize your sockets and wrench neatly. This prevents accidental damage and makes finding tools easier. Label sockets for quick identification.

Check storage areas regularly for signs of moisture or pests. Keeping your tools stored properly extends their lifespan and efficiency.

Frequently Asked Questions

Why Won’t My Sockets Fit On My Impact Wrench?

Your sockets might not fit due to size mismatches. Check if you have impact-rated sockets designed specifically for impact wrenches. Regular sockets can’t withstand the high torque. Ensure compatibility by matching the socket size with your wrench’s drive size, typically either 1/2-inch or 3/8-inch.

Can You Use A Regular Socket On An Impact Wrench?

Using a regular socket on an impact wrench is not recommended. Regular sockets may break under high torque. Impact sockets are designed to handle the stress and prevent accidents. Always choose impact-rated sockets for safety and efficiency.

How Do You Put A Socket On A Wrench?

Align the socket with the wrench’s square drive. Firmly push the socket onto the wrench until it clicks. Ensure it is securely attached before use. Adjust as necessary for a snug fit. Proper attachment prevents slipping during operation, enhancing safety and efficiency.

How Do You Put A Socket On A Torque Wrench?

Align the socket with the torque wrench’s square drive. Push firmly until it clicks into place securely. Ensure it’s tight and doesn’t wobble. Always check the connection before use to avoid accidents.

Conclusion

Attaching a socket to an impact wrench is straightforward. Follow the steps carefully. Safety is crucial, so wear protective gear. Ensure the wrench is compatible with your socket. Secure the socket firmly on the wrench. Double-check the fit before use.

Properly installed sockets prevent accidents. Enjoy smoother operations with your wrench. Regular maintenance keeps your tools efficient. Practice makes perfect. Enhance your skills over time. Keep learning to improve your technique. A well-installed socket boosts your tool’s performance. Happy wrenching!