Have you ever struggled with stubborn bolts that refuse to budge, no matter how much force you apply? Imagine a tool that can make loosening and tightening bolts a breeze, saving you time and effort.

You might have heard of impact wrenches, but do you really know how they work their magic? You’ll discover the secrets behind these powerful tools and how they can transform your DIY projects or professional tasks. Get ready to unlock the mystery of impact wrenches and learn how they could become your new best friend in the toolbox.

Curious? Let’s dive in and find out more!

Mechanics Of Impact Wrenches

Impact wrenches are powerful tools used in construction and automotive industries. They deliver high torque output with minimal effort from the user. Understanding the mechanics of impact wrenches helps in appreciating their efficiency.

How Impact Wrenches Generate Torque

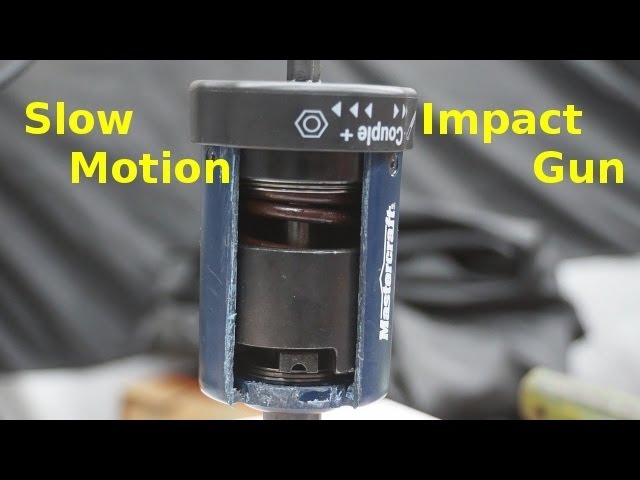

Impact wrenches use a motor to create torque. The motor rotates a hammer inside the tool. This hammer strikes an anvil, producing the powerful torque needed to loosen or tighten bolts.

Role Of The Hammer And Anvil

The hammer stores energy from the motor. When released, it hits the anvil. This sudden impact generates a high torque force. The process repeats multiple times per second, enabling rapid tightening or loosening.

Impact wrenches come in different types. Some are electric, powered by batteries or cords. Others are pneumatic, using compressed air. Each type offers unique benefits, depending on the task at hand.

Advantages Of Impact Wrenches

These tools save time and effort. They handle tough jobs with ease. Their design allows for use in tight spaces. Impact wrenches are reliable and reduce strain on the user’s wrist.

Components Of An Impact Wrench

Impact wrenches work through a combination of components. An electric motor generates power, driving a hammer mechanism. This hammer strikes the anvil, delivering torque to loosen or tighten bolts efficiently. These tools are essential for tasks requiring high torque output without manual effort.

When you pick up an impact wrench, it’s like wielding a tool of power and precision. But what makes this tool tick? Understanding its components can enhance your usage and maintenance skills. Let’s break down the primary components of an impact wrench: the motor, hammer mechanism, and anvil.

Motor

The motor is the heart of an impact wrench. It converts electrical energy into mechanical energy, powering the entire tool. Depending on the model, it can be electric, pneumatic, or hydraulic. Electric motors are common in cordless models, offering mobility and convenience. Pneumatic motors, often found in professional settings, rely on compressed air. Hydraulic motors, though less common, provide extreme torque for heavy-duty applications.

Hammer Mechanism

The hammer mechanism is where the magic happens. It builds up force and delivers rapid, successive blows to the anvil. This mechanism is why an impact wrench can handle stubborn nuts and bolts with ease. Think of it as a cyclist pedaling hard and then releasing that energy all at once. The hammer mechanism stores energy, then releases it in a burst. This design reduces strain on your wrist, making your work safer and more comfortable.

Anvil

The anvil is the final piece in the power puzzle. It’s the part that directly interacts with your sockets and, ultimately, the fasteners. The anvil transfers the force generated by the hammer mechanism to the socket, loosening or tightening bolts effectively. Different anvils suit different tasks. For instance, a half-inch anvil is common for automotive work, while a three-quarter inch might be necessary for industrial projects. Choosing the right anvil ensures you get the job done efficiently. Each component plays a crucial role in the impact wrench’s operation. As you understand these parts, consider how they affect your work. Could a different motor type enhance your efficiency? Would a specific anvil size make your tasks easier? Knowing your tool inside and out empowers you to choose the right one for your needs.

Types Of Impact Wrenches

Impact wrenches are versatile tools used in many industries. They deliver high torque output with minimal effort. Various types of impact wrenches cater to different needs. Understanding each type helps in choosing the right tool for specific tasks.

Corded Electric

Corded electric impact wrenches are powerful and reliable. They draw energy directly from an electrical outlet. This ensures consistent power without battery concerns. Suitable for heavy-duty tasks, they offer steady performance. Their downside is limited mobility due to the cord.

Cordless Battery-powered

Cordless battery-powered impact wrenches provide flexibility. No cords mean easy movement around the workspace. Rechargeable batteries offer convenience but require periodic charging. Ideal for tasks requiring mobility. They are less powerful than corded versions but still effective.

Pneumatic

Pneumatic impact wrenches use compressed air for operation. They are common in automotive and industrial settings. Highly efficient, these tools deliver strong torque. They rely on an air compressor, limiting portability. Perfect for environments with a steady air supply.

Credit: www.rongpeng.com

Torque Power Explained

An impact wrench is a powerful tool. It works by delivering high torque. This tool is essential in various industries. Many people confuse torque with speed. Understanding torque power is key to using an impact wrench effectively. Let’s dive into the details of torque power.

Torque Vs. Speed

Torque and speed are not the same. Torque measures the turning force of the wrench. Speed refers to how fast the tool spins. High torque is crucial for tough jobs. Speed is less important in these tasks. Speed matters when dealing with less resistance. Balancing torque and speed is vital for efficiency. Choosing the right setting improves performance.

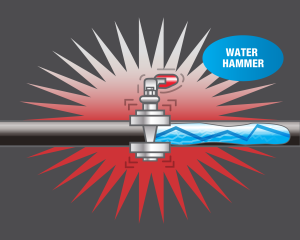

Importance In Fastening

Fastening tasks need high torque. This ensures bolts are tight and secure. Loose bolts can cause accidents. High torque prevents this risk. An impact wrench with high torque saves time. It reduces manual effort. This tool is ideal for automotive and construction tasks. Proper torque application leads to better results. It extends the life of fastened components.

Applications Of Impact Wrenches

Impact wrenches are versatile tools that find their way into various domains. Their powerful torque capabilities make them indispensable for tasks requiring quick and efficient fastening and loosening. Whether you are a car enthusiast, a construction worker, or part of a manufacturing team, these tools can significantly ease your workload. Let’s delve into the fascinating applications of impact wrenches across different industries.

Automotive Repairs

Imagine struggling with stubborn lug nuts while changing a tire. An impact wrench can save you time and energy, swiftly removing even the tightest nuts. These tools are not just limited to tire changes. They are essential for engine repairs, suspension work, and other automotive tasks that require precision and power.

Have you ever had a project where every bolt seemed welded in place? Impact wrenches can make you feel like a superhero, effortlessly overcoming such challenges. Their ease of use and reliability make them a favorite in any garage.

Construction Projects

In construction, time is money. Impact wrenches help you work faster on projects involving large bolts and nuts. Be it erecting steel structures or assembling scaffolding, these tools ensure tasks are completed efficiently.

Think of those days when manual wrenches left you exhausted. With an impact wrench, you can maintain your pace and quality without the physical strain. It’s like having an extra pair of hands to help you get the job done.

Manufacturing And Assembly

In manufacturing, precision is key. Impact wrenches provide consistent torque, critical for assembling machinery and equipment. They reduce the risk of over-tightening, ensuring components fit perfectly.

Consider the complexity of assembling a conveyor belt system. An impact wrench speeds up the process, maintaining accuracy and reliability. This efficiency can significantly boost productivity on the assembly line.

Have you ever wondered how much impact wrench could improve your work efficiency? From automotive repairs to construction projects and manufacturing, they offer practical solutions that enhance productivity and ease. Next time you’re faced with a tough bolt, remember the power of an impact wrench and make your task simpler.

Selecting The Right Impact Wrench

Impact wrenches deliver high torque output with minimal effort. They work using a hammering mechanism. This mechanism rapidly rotates and strikes, making it easy to loosen or tighten bolts.

Selecting the right impact wrench can transform your projects. Whether you’re a professional or a DIY enthusiast, choosing the best tool is crucial. An impact wrench is a powerful tool used for loosening or tightening nuts and bolts. To make an informed choice, consider the following factors.

Assessing Torque Requirements

Understand the torque needed for your tasks. Torque measures the turning force of the wrench. Different jobs require different torque levels. For automotive work, higher torque is essential. Light-duty tasks need less torque. Always match the wrench’s torque to your project’s demands.

Considering Weight And Size

Evaluate the weight and size of the wrench. A lighter tool is easier to handle. Compact designs are ideal for tight spaces. Heavy wrenches may cause fatigue during long use. Balance is key. Choose a tool that feels comfortable in your hands.

Battery Life And Charging

For cordless models, battery life is vital. Long-lasting batteries ensure uninterrupted work. Consider how fast the battery charges. Quick-charging features save time. Some models offer removable batteries. This allows for easy swaps during extended use. Choose a battery that fits your work schedule.

Maintenance Tips

Impact wrenches use compressed air or electricity to rapidly turn bolts and nuts. They deliver high torque output with minimal effort. Regularly clean and lubricate parts to ensure smooth operation and extend tool life.

Maintaining an impact wrench is crucial for ensuring its longevity and performance. Just as you would oil a squeaky door hinge, your impact wrench needs a little TLC to keep working smoothly. Let’s dive into some practical maintenance tips that you can easily follow at home.

Regular Cleaning

Dust and debris can accumulate in your impact wrench, affecting its performance. After every use, wipe down the exterior with a clean cloth and remove any dirt from the air vents. You might be surprised how much grime can sneak into those small crevices.

Lubrication

Keeping your impact wrench lubricated ensures it operates without unnecessary friction. Use a few drops of oil in the air inlet before each use to keep the motor running smoothly. This small step can prevent rust and extend the life of your tool.

Inspecting Wear And Tear

Regularly check your impact wrench for any signs of wear and tear. Look for cracked housings or loose bolts, which can indicate more significant issues. Addressing these early can save you from costly repairs or replacements. Taking care of your impact wrench might seem like a chore, but it’s worth it. Have you checked your wrench lately? Doing so could make all the difference in its performance and lifespan.

Credit: onevantool.com

Credit: www.youtube.com

Frequently Asked Questions

What Are The Disadvantages Of Impact Wrenches?

Impact wrenches can be noisy and produce vibrations, leading to discomfort. They require regular maintenance and can be expensive. Users may over-tighten bolts, risking damage. Their weight might cause user fatigue. Air-powered models need a compressor, adding to costs. Proper training is essential to ensure safety during use.

When Should You Not Use An Impact Wrench?

Avoid using an impact wrench on delicate or precision fasteners. It can damage threads or over-tighten. Manual tools are better for small screws or non-metal materials. Use caution when handling sensitive equipment or assembling parts requiring specific torque settings. Always ensure the tool matches the job requirements.

Why Can’t You Use Regular Sockets With Impact Wrench?

Regular sockets can crack under impact wrench pressure. They lack durability and strength for high-torque applications. Impact sockets are specially designed to withstand intense force, ensuring safety and efficiency. Using regular sockets risks damage to tools and fasteners, potentially leading to costly repairs.

Always opt for impact-rated sockets with impact wrenches.

How Do Impact Wrenches Have So Much Torque?

Impact wrenches generate high torque using a powerful motor and a hammer mechanism. The motor drives rotational energy, while the hammer delivers sudden force. This combination allows for efficient loosening or tightening of nuts and bolts. Their design ensures maximum torque output, making them ideal for heavy-duty applications.

Conclusion

Impact wrenches are essential for fast, efficient work. They save time and reduce effort. The power they deliver is impressive, making tough jobs easier. With simple mechanics, they are easy to understand. Perfect for DIY enthusiasts and professionals alike. Investing in a quality impact wrench enhances productivity.

Choose one that fits your needs. Remember to maintain it well for long-lasting service. Explore options and find the best fit. Your projects will benefit from this powerful tool. Understanding its function helps maximize its potential. Happy wrenching!