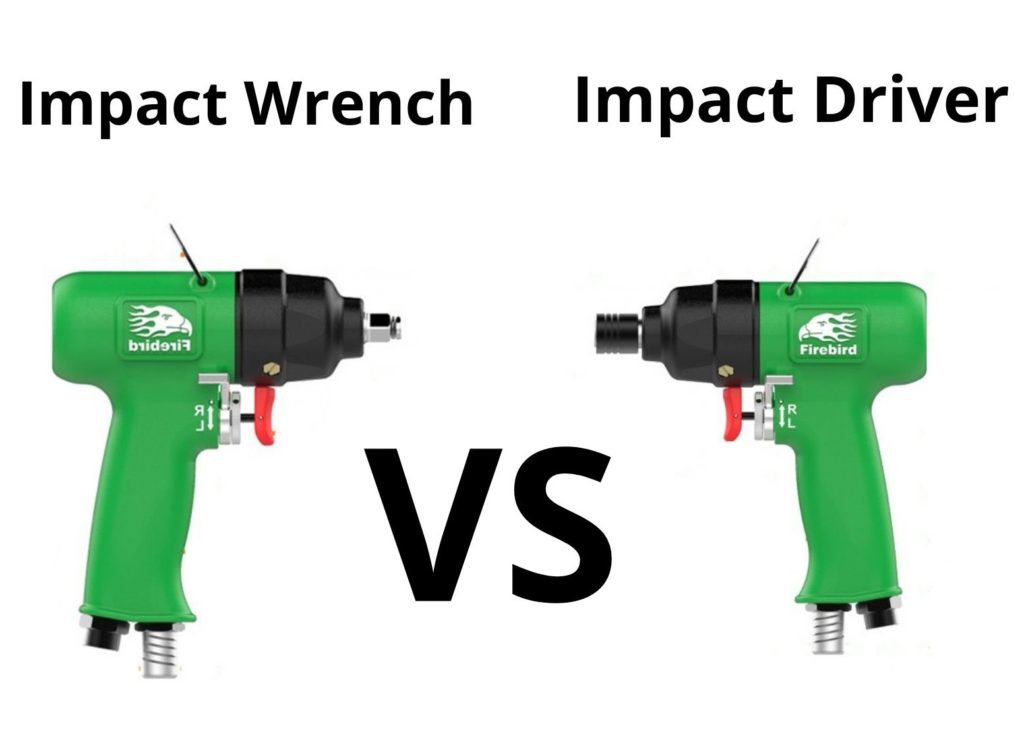

Ever found yourself standing in the tool aisle, staring at an impact driver and an impact wrench, wondering which one you really need? You’re not alone.

These two tools might look similar, but they serve different purposes and can make your projects much easier—or harder—depending on which one you choose. Understanding the difference between an impact driver and an impact wrench can save you time, money, and a lot of frustration.

Imagine knowing exactly which tool will get the job done faster without damaging your materials. This article will clear up any confusion and empower you to make the right choice for your next DIY project or professional task. Curious to find out which tool fits your needs perfectly? Keep reading, and you’ll soon be the go-to expert among your friends and family when it comes to choosing the right tool for the job.

Basic Functionality

The basic functionality of impact drivers and impact wrenches often confuses even seasoned DIY enthusiasts. While they may appear similar at first glance, their operations and applications are distinct. Understanding these differences can greatly enhance your efficiency in various projects. Imagine working on assembling furniture or tackling automotive repairs with the right tool by your side. It’s all about choosing the right equipment for the task at hand.

Impact Driver Operation

Impact drivers are your go-to tool for driving screws and bolts into dense materials. They are compact and lightweight, making them perfect for overhead work or tight spaces. The impact driver operation involves a combination of rotational motion and quick bursts of impact, which helps drive screws effortlessly without wearing your wrist out.

Think of the time you struggled to drive a long screw into hardwood with a regular drill. An impact driver would have made that task a breeze. Its functionality allows the screw to penetrate tough materials without the need for pre-drilling. Have you ever considered how much time you could save with this tool in your toolkit?

Impact Wrench Operation

Impact wrenches, on the other hand, are built for heavy-duty tasks like loosening or tightening large nuts and bolts. They are larger and more powerful than impact drivers, typically used in automotive and construction settings. Their operation involves delivering high torque output with minimal effort on your part, which is crucial when dealing with stubborn fasteners.

Picture yourself changing a car tire with ease—an impact wrench makes it possible. This tool can remove lug nuts in seconds, saving you from the frustration of manual wrenches. Consider how much easier your maintenance tasks could be with the right wrench at your disposal.

Have you ever wondered if you’re using the right tool for your project? Understanding the basic functionality of these tools can transform your approach to DIY tasks. Are you ready to make your work more efficient?

Design And Build

Understanding the design and build of an impact driver and an impact wrench is key for choosing the right tool. Both tools have unique features and purposes. Their design affects how they perform tasks in various settings. Let’s explore these differences in design and build.

Size And Weight

Impact drivers are compact. They fit in tight spaces easily. Their lightweight design reduces hand fatigue during long use. This makes them ideal for DIY projects.

Impact wrenches are larger and heavier. They provide more power for tough jobs. The size can be a challenge in cramped areas. But the added weight helps in handling bigger tasks efficiently.

Grip And Handle Design

Impact drivers have ergonomic grips. This ensures comfort during extended use. The handle design provides good control over the tool. It reduces the strain on your wrists.

Impact wrenches also focus on comfort. They often have rubber grips. This minimizes slippage during operation. The handle design supports powerful torque delivery. It allows for better leverage during tough jobs.

Power Sources

When choosing between an impact driver and an impact wrench, understanding their power sources is crucial. How they are powered can significantly affect your decision, especially if you plan to use them frequently. Let’s dive into the different power options available for these tools.

Corded Vs Cordless

Both impact drivers and impact wrenches come in corded and cordless versions. Corded tools offer uninterrupted power, making them ideal for long, demanding tasks. You don’t have to worry about battery life, just plug them in and get to work. However, the cord can limit your mobility.

On the other hand, cordless tools provide freedom of movement. Imagine being able to move around your garage or workshop without being tethered to an outlet. Cordless versions are perfect for quick jobs or when working in areas without easy access to power sockets.

Battery Life Considerations

If you choose a cordless impact driver or wrench, battery life becomes an important factor. You want a tool that can last through your project without needing constant recharging. Consider tools with lithium-ion batteries—they tend to hold power longer and charge faster.

Have you ever been mid-project, only to find your battery dying? To avoid this, keep an extra battery on hand. This simple trick can save you time and keep your workflow smooth. Also, check the manufacturer’s specs; some models boast longer battery lives than others.

How do you plan to use your impact tool? Whether you’re looking at corded or cordless options, think about how the power source will affect your tasks. Your choice can make all the difference in efficiency and ease of use. Would you prefer constant power or ultimate flexibility?

Credit: www.paceassemblytools.com

Torque And Speed

When you’re working on a project, choosing the right tool can make all the difference. Two powerful tools often discussed are the impact driver and the impact wrench. Understanding their torque and speed can help you decide which one suits your needs best. Let’s dive into these crucial aspects.

Torque Levels

Torque is the force that causes rotation. In simple terms, it’s what allows these tools to drive screws or bolts into materials. Impact drivers are known for their moderate torque levels, making them ideal for driving screws into wood or metal.

Think about assembling furniture or hanging shelves. An impact driver offers enough torque to get the job done without overwhelming the material. On the other hand, impact wrenches boast high torque levels. They’re perfect for tasks like loosening lug nuts on a car wheel or heavy-duty construction projects.

Picture this: you’re changing a tire, and those lug nuts are stubborn. The impact wrench’s torque power saves the day, effortlessly loosening them. How often have you struggled with a simple screwdriver, wishing for more power?

Speed Variations

Speed is equally important when choosing between these tools. Impact drivers typically operate at higher speeds, enabling you to complete tasks quickly. Imagine you’re installing drywall. The fast-paced action of an impact driver helps you finish the job in less time.

However, speed isn’t always your friend. When precision is key, you might prefer a slower tool. Impact wrenches usually operate at slower speeds but offer consistent power. This makes them reliable for tasks requiring steady pressure, like assembling machinery.

Ever felt rushed and made mistakes? With an impact wrench, you have the control to work at a pace that ensures accuracy. Do you prefer speed or precision in your projects?

Choosing between an impact driver and an impact wrench boils down to what you value more: torque or speed. Consider your projects and how these tools fit into your toolkit. Whether it’s home improvement or professional work, knowing these differences can guide you to the best choice for your needs.

Common Uses

Impact drivers and impact wrenches are essential tools for various tasks. Each tool serves specific purposes in different applications. Understanding their common uses helps in choosing the right tool for the job. Let’s explore how these tools are typically used.

Typical Applications For Impact Drivers

Impact drivers excel in fastening screws and bolts. They are ideal for woodworking and construction projects. Their compact design allows easy maneuvering in tight spaces. With high torque, they handle stubborn screws effortlessly. Electricians use them for installing electrical boxes. They are also handy in assembling furniture quickly. Homeowners find them useful for DIY tasks.

Typical Applications For Impact Wrenches

Impact wrenches are perfect for heavy-duty tasks. Mechanics use them for automotive work, like loosening lug nuts. They deliver powerful torque for industrial applications. In construction, they tighten large bolts on steel structures. Impact wrenches are also used in equipment maintenance. Their strength is unmatched in demanding environments. Tire shops rely on them for rapid tire changes.

Attachments And Accessories

Understanding the right attachments and accessories can enhance tool performance. Each tool has specific add-ons that cater to its functionality. Knowing these can make tasks easier and more efficient. Let’s explore the attachments and accessories for impact drivers and impact wrenches.

Impact Driver Bits

Impact driver bits are essential for effective drilling. These bits are designed to handle high torque. They come in various shapes and sizes to fit different screws. High-quality materials ensure durability and precision. Magnetic tips help keep screws in place, preventing slips.

Different bits serve different purposes. Philips, flathead, and hex are common types. For specialized tasks, torx and square bits are useful. Choosing the right bit ensures smooth and efficient operation. Investing in a good bit set can prolong tool life.

Impact Wrench Sockets

Impact wrench sockets are crucial for handling nuts and bolts. Made from strong materials, they withstand high pressure. These sockets come in metric and standard sizes. Each size fits specific bolt heads, ensuring a snug fit.

Deep sockets are useful for reaching recessed bolts. Shallow sockets are ideal for tight spaces. A universal joint can increase flexibility, allowing for angled access. Having a diverse socket set can tackle various automotive and construction tasks.

Color-coded sockets enhance organization and speed. They help quickly identify the needed size. Proper storage prevents loss and damage, keeping your tools ready for action.

Price And Value

Understanding the price and value of tools helps make informed decisions. Impact drivers and impact wrenches differ in cost and long-term value. Knowing these differences aids in choosing the right tool for your needs.

Cost Considerations

Impact drivers are generally more affordable than impact wrenches. Their simpler design and functionality keep costs low. For DIY enthusiasts, this makes them a budget-friendly choice. Prices for impact drivers usually range from $50 to $150.

Impact wrenches, on the other hand, are often more expensive. They offer higher torque and power, which increases their price. Professional-grade models can cost between $100 and $300. This price range reflects their advanced features and capabilities.

Long-term Investment

Consider the long-term value of each tool. Impact drivers are versatile and useful for light tasks. They handle screws and small bolts efficiently. This makes them a good investment for home projects.

Impact wrenches provide value for heavy-duty tasks. They excel in automotive and industrial settings. Their durability and power justify the higher price. Investing in a quality impact wrench pays off over time.

Choose based on your tool needs and usage frequency. This ensures the best value for your money.

Credit: www.youtube.com

Safety Features

When working with tools like impact drivers and impact wrenches, safety features are crucial. They ensure that your hands and wrists are protected from the powerful forces these tools exert. Understanding these features can make your projects safer and more efficient.

Safety Mechanisms In Impact Drivers

Impact drivers are designed with user safety in mind. One common feature is the ergonomic grip, which reduces hand fatigue and offers better control. Think about the last time you struggled with a screwdriver—an impact driver can make that job much easier without straining your wrist.

Another safety aspect is the variable speed trigger. This allows you to adjust the speed according to the task, preventing the tool from slipping or damaging materials. It’s like having a car with adjustable gears; you wouldn’t want to speed through a school zone, right?

Many impact drivers come with LED lights. These illuminate your work area, reducing the risk of accidents in dimly lit spaces. Imagine working under a sink or in a tight spot; good lighting can prevent mishaps.

Safety Mechanisms In Impact Wrenches

Impact wrenches, known for their power, also prioritize safety. They often include a robust casing to protect against accidental drops. It’s like having a phone case that absorbs shocks, ensuring your tool remains intact.

Some models offer anti-vibration handles. This feature minimizes the vibrations felt by your hands, reducing fatigue and potential long-term damage. Have you ever tried holding a jackhammer? The shaking can be intense, but with an anti-vibration handle, your grip stays steady.

Impact wrenches might also include torque control settings. This helps prevent over-tightening, which could damage bolts or the tool itself. Picture a scenario where you’re assembling a delicate piece of furniture; precise torque control makes all the difference.

Both tools have their unique safety features, tailored to their specific uses. So, when choosing between an impact driver and an impact wrench, consider not just the task at hand but also the safety features that will protect you in the long run.

What safety features matter most to you when picking a tool? Share your thoughts and let’s make safety a top priority in our DIY adventures.

Choosing The Right Tool

Choosing the right tool for your project can save time and effort. Impact drivers and impact wrenches are both powerful tools. But they serve different purposes. Knowing their differences helps in selecting the best one. Consider your project’s needs, budget, and tool usage frequency.

Assessing Project Needs

Each project demands specific tools. Impact drivers excel in driving screws and bolts. They are perfect for woodwork and light metal tasks. On the other hand, impact wrenches are suited for heavy-duty tasks. Changing tires or handling large bolts needs their strength. Identify the project’s requirements first.

Budget And Frequency Of Use

Budget plays a crucial role in selecting tools. Impact drivers are generally cheaper. They are ideal for home use or small projects. Impact wrenches cost more but offer greater torque. Consider how often the tool will be used. Frequent users might invest in a quality impact wrench. Occasional users might prefer a budget-friendly impact driver.

Credit: www.protoolreviews.com

Frequently Asked Questions

Can I Use My Impact Driver To Remove Lug Nuts?

Yes, you can use an impact driver to remove lug nuts. Ensure it has enough torque for tough jobs. Use the correct socket size to avoid stripping the nuts. Impact wrenches are often more effective for lug nuts than drivers.

Always follow safety precautions when using power tools.

When Should You Not Use An Impact Wrench?

Avoid using an impact wrench on delicate materials or precision fasteners. Use it only for tasks requiring high torque. Ensure compatibility with the fastener size and type. Avoid situations where precise torque control is crucial. Over-torquing can lead to damage or unsafe conditions.

Can An Impact Wrench Be Used As An Impact Drill?

An impact wrench isn’t designed for drilling tasks. It lacks the precision and compatibility with drill bits. For drilling, use an impact drill or a regular drill. Impact wrenches excel in loosening and tightening bolts and nuts. Always choose the right tool for specific tasks to ensure efficiency and safety.

What Would You Use An Impact Driver For?

An impact driver is ideal for driving screws and bolts efficiently. It delivers high torque for tough tasks. Use it for building decks, assembling furniture, or working on construction projects. Its compact design allows access to tight spaces, making it versatile and essential for DIY enthusiasts and professionals alike.

Conclusion

Choosing between an impact driver and an impact wrench? Understand your needs first. Impact drivers handle screws and small bolts. Perfect for lighter tasks. Impact wrenches offer more torque. Ideal for larger bolts and nuts. Consider the job type. Think about the tool’s power.

Reflect on your usage frequency. Both tools serve different purposes. Each has unique benefits. Evaluate these before buying. Make an informed decision. The right tool enhances efficiency. Save time and effort. Select wisely for your projects. Enjoy smoother work with the correct tool.