Are you struggling to choose the right circular saw blade? You’re not alone.

With so many options available, it’s easy to feel overwhelmed. Whether you’re a DIY enthusiast or a seasoned professional, understanding saw blade teeth is crucial to your success. Each type of tooth is designed for specific tasks, and selecting the wrong one can lead to poor performance or even damage to your materials.

But don’t worry—this guide will simplify the complexities and give you the confidence to make the right choice. Discover how the correct blade can transform your projects from frustrating to flawless, and keep reading to unlock the secrets of saw blade teeth that every craftsperson needs to know.

Credit: makezine.com

Types Of Circular Saw Blades

Understanding the types of circular saw blades can dramatically change how you approach woodworking projects. Each blade serves a unique purpose, and knowing which to use can make your tasks quicker and cleaner. Let’s dive into the main types of circular saw blades and see how you can make the most out of your saw.

Rip Blades

Rip blades are designed for cutting along the grain of the wood. They have fewer teeth, usually around 24, which allows them to remove material quickly. If you’ve ever tried cutting thick lumber, you know how tough it can be. Rip blades make this task easier by delivering fast, powerful cuts without getting bogged down. Are you looking to speed up your woodcutting? A rip blade might just be your new best friend.

Crosscut Blades

Crosscut blades are your go-to for cutting across the grain. These blades typically have 60 to 80 teeth, providing smoother cuts ideal for precise work like cabinetry. Imagine the satisfaction of seeing a clean edge on your finished piece. Crosscut blades make it possible by minimizing splintering. If precision is what you crave, crosscut blades are worth considering.

Combination Blades

Not sure whether you need a rip or crosscut blade? Combination blades offer the best of both worlds. With around 40 to 50 teeth, these blades can handle a variety of tasks, making them versatile for different projects. Picture yourself tackling multiple types of cuts without changing blades. Combination blades simplify your workflow, saving you time and effort. Could this be the convenience you’ve been missing?

Specialty Blades

Do you have specific materials like metal or plastic to cut? Specialty blades are designed for these unique tasks. They come with features tailored to different materials, ensuring efficient and clean cuts. Imagine cutting through metal like butter, or achieving a flawless finish on acrylic. Specialty blades open up possibilities beyond wood. Are you ready to expand your project horizons?

Choosing the right blade can elevate your woodworking skills. Think about your projects and which blade suits your needs best. As you become more familiar with each type, you’ll find yourself reaching for the perfect blade with confidence. So, what blade will you try next?

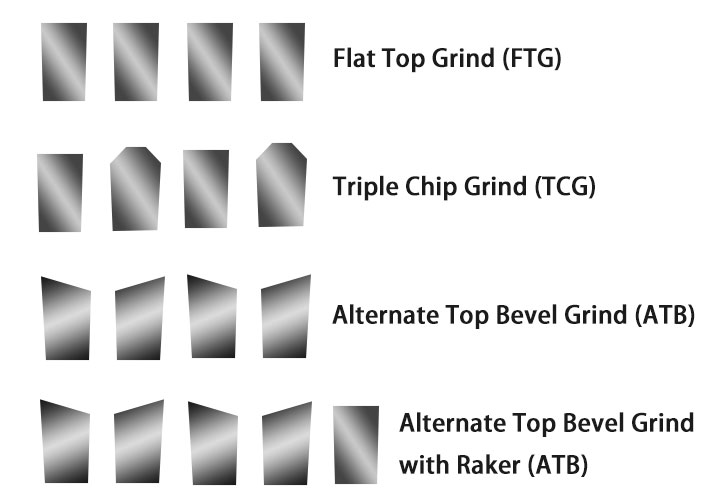

Tooth Geometry

Understanding tooth geometry is key to mastering your circular saw blade’s performance. It shapes the way the blade cuts and directly impacts precision and speed. Whether you’re crafting fine furniture or tackling a home renovation project, choosing the right tooth geometry can make or break your results.

Let’s dive into some common tooth geometries and see what each can offer.

Alternate Top Bevel (atb)

ATB is popular among woodworkers for its versatility. It features teeth angled alternately left and right, enhancing smooth cuts and minimizing splintering. Imagine cutting through plywood with ease—ATB is your go-to for a clean finish.

Do you often find yourself working with delicate materials? Then ATB could save you time and frustration.

Flat Top Grind (ftg)

FTG is the workhorse for ripping lumber. The flat, straight tooth tops make it ideal for fast, rough cuts in solid wood. Picture yourself slicing through a thick oak board without hesitation—that’s FTG in action.

Consider FTG when you need power and speed over finesse.

Triple Chip Grind (tcg)

TCG combines beveled and flat teeth, making it perfect for hard and dense materials like laminates and plastics. It excels in reducing chipping and improving durability. If you’re dealing with tough materials, TCG can be your best ally.

Have you ever struggled with a brittle surface? TCG might be the solution you’ve been looking for.

High Alternate Top Bevel (hi-atb)

Hi-ATB is designed for ultra-smooth cuts, especially in cross-grain wood. The high bevel angle sharpens the cut quality, ideal for fine woodworking projects. Visualize the satisfaction of achieving a flawless edge on a cherry wood cabinet door—Hi-ATB makes it possible.

Are you aiming for perfection in your craft? Hi-ATB could be your secret weapon.

Each tooth geometry has its unique strengths. Consider your project needs and material type. Could experimenting with different geometries improve your cutting technique? The right choice could transform your woodworking experience.

Blade Material Considerations

Choosing the right blade material is crucial for circular saw performance. Steel blades are affordable and suitable for softwood. Carbide-tipped blades offer durability and precision, ideal for hardwood and metal cutting. Understanding these materials helps in selecting the appropriate blade for specific tasks.

When you’re choosing a circular saw blade, the material of the blade teeth is crucial. It can affect the longevity of your blade and the quality of your cuts. Imagine you’re in the middle of a woodworking project, and your blade gives out. Annoying, right? Understanding blade materials can save you from such hassles. Let’s dive into the world of blade materials and see what works best for your needs.

Carbide-tipped Blades

Carbide-tipped blades are popular for their durability and precision. They are known to stay sharp longer than other types. If you’re frequently cutting hardwood or composite materials, carbide-tipped blades can be your best friend. Consider them an investment—though they might cost more upfront, they require less frequent replacement. Have you ever spent more time changing blades than actually cutting? Carbide tips can help reduce that frustration.

Steel Blades

Steel blades are often the go-to for those on a budget. They are less expensive than carbide and work well for softer woods and general-purpose cutting. However, they tend to dull more quickly. If you’re doing occasional home projects, steel blades might be sufficient. But if you find yourself cutting through tougher materials regularly, you might want to reconsider. Is the cost-saving worth the compromise in performance?

Diamond Blades

Diamond blades are the champions of cutting hard materials. They are typically used in masonry and tile work. Their toughness is unmatched, providing clean cuts through concrete and stone. Have you ever tackled a DIY project involving tiles? Diamond blades can make the difference between a smooth cut and a jagged mess. While they might not be necessary for woodwork, knowing their strength could open up new project possibilities for you. Understanding blade materials can transform your cutting experience. What material are you leaning towards for your next project?

Credit: www.scosarg.com

Selecting The Right Tooth Count

Choosing the right tooth count for a circular saw blade can greatly impact cutting efficiency and finish quality. More teeth provide cleaner cuts, ideal for fine woodworking. Fewer teeth cut faster, suitable for rough materials. Understanding these differences helps in selecting the perfect blade for your project.

Selecting the right tooth count for a circular saw blade is crucial. It impacts the quality and efficiency of your cuts. Each task requires a specific number of teeth. Understanding this helps achieve precision and speed.

Low Tooth Count For Rip Cuts

Blades with fewer teeth excel in rip cuts. Rip cuts follow the wood grain. Low tooth count blades remove material quickly. This results in faster cuts. They produce rougher finishes but are efficient. Ideal for cutting thick wood pieces.

High Tooth Count For Crosscuts

High tooth count blades are best for crosscuts. Crosscuts go against the wood grain. These blades provide smooth, clean finishes. More teeth mean less material removal per tooth. This reduces splintering and tear-outs. Ideal for fine woodworking tasks.

Balancing Tooth Count For Versatility

Balancing tooth count offers versatility. A medium tooth count suits various tasks. These blades handle both rip and crosscuts. Not perfect for specialized tasks but useful for general work. Ideal for those needing one blade for multiple uses.

Maintenance And Care Tips

Maintaining your circular saw blade is crucial for its longevity and performance. Regular care keeps the blade sharp and efficient. It also prevents unnecessary wear. Proper maintenance involves cleaning, sharpening, and storing the blade correctly.

Cleaning The Blade

Regular cleaning removes built-up pitch and resin. Use a brush or cloth to wipe off debris. A mild detergent solution can help break down stubborn grime. Rinse thoroughly and dry the blade completely to prevent rust.

Sharpening Techniques

Sharpening ensures the blade cuts smoothly. Use a diamond file or sharpening stone. Follow the teeth angle for precision. Consider professional sharpening for optimal results. Regular sharpening extends the blade’s lifespan.

Storing Blades Safely

Proper storage prevents damage and injury. Store blades in a dry place. Use blade protectors to shield them. Hang blades or lay them flat. Avoid stacking to prevent distortion. Safe storage maintains blade integrity.

Safety Precautions

Ensure personal safety by wearing protective gear when using a circular saw. Keep fingers clear of the blade to avoid accidents. Double-check the blade’s sharpness and secure it properly before starting your work.

Ensuring safety is crucial when using a circular saw. Understanding the right precautions can prevent accidents. Proper handling and gear are key. Awareness of kickback risks is vital. Let’s delve into these essential safety measures.

Proper Handling

Handle the circular saw with care. Hold it firmly with both hands. Keep your fingers away from the blade. Ensure a stable stance while cutting. Always turn off the saw before making adjustments. Inspect the blade for damage before use. A damaged blade can be dangerous. Align the saw correctly with your cutting line.

Using Safety Gear

Wearing safety gear can protect you. Safety glasses shield your eyes from debris. Ear protection reduces noise damage. Wear gloves for a better grip and hand safety. Use a dust mask to avoid inhaling particles. Steel-toed boots can protect your feet. Ensure your clothing is snug and not loose.

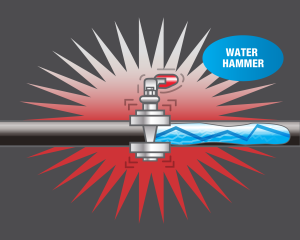

Avoiding Kickback

Kickback is a sudden, forceful reaction. It occurs when the saw binds or stalls. Keep the blade sharp to minimize binding. Do not cut materials that are too hard. Maintain a firm grip to control the saw. Stand to the side, not directly behind the saw. This reduces the risk of injury if kickback happens. Keep the blade guard functioning properly.

Credit: handtoolessentials.com

Frequently Asked Questions

What Is The Best Tooth Count For Circular Saw Blades?

Choose a tooth count based on the material. Use 24-30 teeth for rough cuts, 40-80 teeth for smooth wood cuts, and 80-120 teeth for fine finishes. More teeth provide cleaner cuts, while fewer teeth remove material quickly. Select the right blade for optimal results.

Is It Better To Have More Or Less Teeth On A Circular Saw?

The number of teeth on a circular saw affects the cut quality. More teeth provide smoother cuts, ideal for fine woodworking. Fewer teeth cut faster and are suitable for rough cuts or thicker materials. Choose based on your project needs for optimal results.

Which Way Do The Teeth Go On A Circular Saw Blade?

Position the teeth on a circular saw blade to face forward, towards the rotation direction. This ensures efficient cutting. Install the blade following the manufacturer’s arrows or markings for correct orientation. Proper installation enhances performance and safety. Regularly check for wear and replace blades as needed for optimal operation.

What Is A 60 Tooth Saw Blade Used For?

A 60 tooth saw blade is ideal for making smooth, precise cuts in wood, plywood, and laminate. It reduces splintering and tear-out, ensuring a clean finish. This blade is perfect for crosscutting and fine woodworking projects, offering superior quality and accuracy.

Conclusion

Choosing the right circular saw blade teeth is essential. It impacts cut quality and efficiency. Different projects require different teeth configurations. Consider material type and desired finish. Always check your saw’s compatibility with blade types. Regular maintenance extends blade life.

Clean and sharpen as needed. Safety should be your priority. Wear protective gear when using your saw. A well-suited blade enhances performance. It ensures precise and smooth cuts. Take time to understand blade options. Make informed decisions for better outcomes.

This guide helps in selecting the perfect blade. Your projects will benefit greatly.