Have you ever tried to cut through wood with a dull circular saw blade? If so, you know how frustrating it can be.

The blade gets stuck, the cuts are rough, and the entire process feels like a workout. But what if there was a simple way to ensure your saw blade slices through materials like butter every time? You’ll discover the secrets to sharpening a circular saw blade, turning it from a rusty tool into a precision instrument.

Sharpening your blade not only enhances your cutting efficiency but also extends the life of your saw. Imagine saving time and money while achieving perfectly smooth cuts with ease. Don’t let a dull blade hold you back. Keep reading to learn how you can sharpen your circular saw blade like a pro.

Credit: www.youtube.com

Tools Required

Circular saw blade sharpening requires specific tools such as a diamond file, vise, and blade cleaning solution. Proper alignment and careful use of these tools ensure optimal blade performance and extended lifespan. Regular maintenance keeps blades sharp and efficient for precision cutting tasks.

Sharpening a circular saw blade might seem daunting, but with the right tools, it’s quite manageable. The tools you choose can make or break the sharpening process, affecting both the blade’s performance and your safety. Are you ready to explore the essentials that will ensure a smooth and successful sharpening experience?

Essential Tools For Sharpening

A reliable file set is indispensable. A diamond file or a flat file works wonders for most blades. Choose a file that matches the size of the blade’s teeth for precise sharpening.

Using A Vise For Stability

A bench vise is crucial for holding the blade securely in place. Without it, the blade can slip, leading to uneven sharpening or, worse, potential injury. Always ensure the blade is stable before you start working on it.

Safety Gear: A Must-have

Safety shouldn’t be an afterthought. Equip yourself with safety goggles and gloves. They protect your eyes from metal filings and your hands from sharp edges. It’s easy to overlook safety, but it’s vital every time you sharpen.

Marker For Precision

A simple permanent marker can be a game-changer. Use it to mark your starting point on the blade. This ensures you sharpen each tooth evenly and don’t lose track of your progress.

Cleaning Supplies

Before sharpening, a clean blade is essential. Use a wire brush or cleaning solution to remove any debris or resin build-up. A clean blade not only sharpens better but also performs better once reinstalled.

Optional: Sharpening Jig

For those who prefer precision and ease, a sharpening jig can be a worthy investment. It holds the file at the right angle, ensuring uniform sharpening across all teeth. While not necessary, it can make the process much smoother. Do these tools sound familiar? Perhaps you already have some in your toolbox. By gathering these items, you set yourself up for a successful sharpening process. What tool will you start with on your next sharpening adventure?

Credit: www.jungheinrich-profishop.co.uk

Safety Precautions

Ensuring safety is crucial when sharpening a circular saw blade. Wear protective gloves and goggles to prevent injuries. Secure the blade firmly to avoid any movement during the sharpening process.

Sharpening a circular saw blade requires strict attention to safety. Handling sharp tools demands care to prevent accidents. Always prioritize safety precautions to protect yourself and your surroundings. This ensures a safe and effective sharpening process.

Wear Protective Gear

Always wear safety goggles to protect your eyes from flying metal shards. Thick gloves are essential to shield your hands from cuts and abrasions. Consider wearing a dust mask to avoid inhaling fine dust particles.

Disconnect The Power Source

Ensure the saw is unplugged from the power source before starting. If using a battery-operated saw, remove the battery. This prevents accidental start-ups during the sharpening process.

Secure The Blade

Use a sturdy vice to hold the blade in place. A secure blade prevents slips and ensures precise sharpening. Double-check the blade’s stability before proceeding.

Work In A Well-lit Area

Ensure adequate lighting in your workspace. Good lighting helps you see the blade’s edges clearly. This reduces mistakes and enhances safety during sharpening.

Keep Your Workspace Organized

Maintain a tidy workspace free from clutter. Keep all tools and materials within easy reach. This reduces the risk of accidents and improves efficiency. By adhering to these safety precautions, you ensure a smooth sharpening experience. Stay safe and keep your tools in top condition.

Removing The Blade

Removing the blade from a circular saw is crucial for sharpening. A dull blade reduces efficiency and increases the risk of accidents. It’s important to handle the removal with care and precision.

Turn Off And Unplug The Saw

Safety first. Always turn off your saw. Unplug it from the power source before any work. This prevents accidental starts, which can be dangerous.

Place The Saw On A Stable Surface

Ensure your saw rests on a flat, stable surface. This helps maintain balance while working. A wobbly surface can lead to slips, causing injury.

Use A Wrench To Loosen The Arbor Nut

Locate the arbor nut that holds the blade. Use a wrench to loosen it. Turn counterclockwise to unscrew. Ensure a firm grip while doing this.

Remove The Blade Guard

The blade guard protects users from direct contact. Carefully lift it out of the way. This gives easy access to the blade for removal.

Slide The Blade Off The Arbor

Once the nut is loose, slide the blade off. Handle it carefully, as blades are sharp. Place the blade aside in a safe spot.

Cleaning The Blade

Sharpening a circular saw blade involves cleaning it first. Remove the blade and scrub off dirt and rust. Use a wire brush for stubborn spots. A clean blade ensures smoother sharpening and better performance.

Cleaning a circular saw blade is crucial before sharpening. Dirt, dust, and sap can affect performance. A clean blade leads to better cuts and extends the blade’s life. Follow these simple steps to clean your circular saw blade effectively.

Step 1: Remove The Blade

First, ensure the saw is unplugged. Safety first. Then, remove the blade carefully. Use a wrench if needed. Secure the blade to prevent it from moving. This ensures safe handling.

Step 2: Prepare Cleaning Solution

Create a cleaning solution with warm water and dish soap. Simple and effective. Alternatively, use a commercial blade cleaner. Both options work well. Choose based on preference and availability.

Step 3: Soak The Blade

Place the blade in the cleaning solution. Let it soak for 15-20 minutes. This helps loosen grime and resin. Be patient. It makes cleaning easier.

Step 4: Scrub The Blade

Use a soft brush to scrub the blade. Gently remove residue and dirt. Pay attention to teeth and edges. Avoid using steel wool. It can damage the blade.

Step 5: Rinse And Dry

Rinse the blade with clean water. Ensure all soap is removed. Dry the blade immediately with a soft cloth. Prevents rust and corrosion. Store the blade in a dry place. Regular cleaning keeps your circular saw in top condition. Effective cleaning improves performance and safety. Follow these steps for a clean and efficient blade.

Marking The Teeth

Marking each tooth on a circular saw blade ensures precise sharpening. Use a marker to highlight every tooth. This helps maintain consistency and balance during sharpening.

Sharpening a circular saw blade can feel like an intricate dance. One of the key steps is marking the teeth. Without proper marking, you might sharpen the same tooth multiple times or skip some entirely. This step ensures that each tooth receives equal attention and your blade performs efficiently when cutting through wood or other materials.

Understanding The Importance Of Marking

The process of marking the teeth isn’t just a mundane task. It’s a way to save time and effort. Think about it: if you’ve ever sharpened a saw blade and wondered why it still didn’t cut smoothly, you might have skipped a few teeth accidentally. Proper marking eliminates guesswork.

Choosing The Right Marker

Select a marker that is easily visible. A permanent marker works well because it stays on the metal surface without smudging. You don’t need fancy tools—a simple marker from your desk will do the trick.

Developing Your Marking Strategy

Decide on a marking strategy. You can start at the first tooth and work your way around clockwise. This systematic approach helps keep track of which teeth have been sharpened. It’s a simple yet effective way to ensure no tooth goes unnoticed.

Marking As A Personal Ritual

Think of marking the teeth as a personal ritual. It’s a moment to slow down and focus. Every time you sharpen a blade, you’re investing in precision and efficiency. Reflect on how this small task improves your woodworking projects.

What If You Forget To Mark?

Missing this step can lead to uneven sharpening. A blade with unevenly sharpened teeth can cause rough cuts and increased wear on the motor. Take a moment to consider how much smoother your projects will be if you consistently mark the teeth.

Consistency Is Key

Mark the teeth every time you sharpen. This consistency transforms your maintenance routine into a reliable process. It’s a small habit that has a big impact on your tool’s performance. Marking the teeth is not just about preparation. It’s a step that can save you from future frustrations. Try it out the next time you sharpen your circular saw blade, and notice the difference it makes.

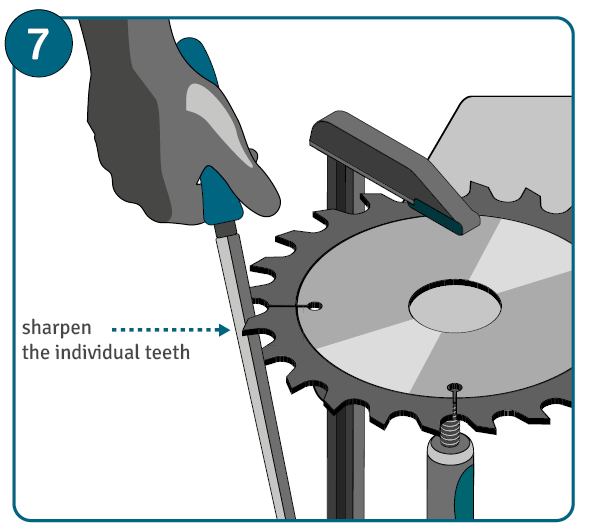

Sharpening Techniques

Sharpening a circular saw blade requires precision and patience. Begin by securing the blade firmly in a vice. Use a diamond file to carefully grind each tooth, maintaining consistent angles. Regular maintenance ensures smooth cuts and prolongs blade life.

Sharpening Techniques Have you ever noticed how a dull circular saw blade slows you down? It can make even the simplest cuts frustrating. Sharpening your blade not only extends its life but also makes your tasks smoother and faster. Let’s explore some effective sharpening techniques. Which one suits your needs best?

Using A File

Sharpening a circular saw blade with a file is a straightforward method. It’s ideal if you enjoy hands-on work and have the patience for detail. First, remove the blade from the saw. Secure it in a vice to keep it steady. Use a flat file to gently sharpen each tooth. Ensure the file follows the angle of the blade’s bevel. A few strokes per tooth can make a noticeable difference. While filing, consistency is key. Uneven sharpening can lead to poor cuts. Have you tried filing before? It’s a rewarding skill to master.

Using A Dremel

A Dremel tool offers a quicker way to sharpen your blade. It’s perfect for those who prefer a bit of technology in their toolkit. Attach a small grinding stone to the Dremel. Set the blade securely in a vice. Gently guide the Dremel along each tooth, maintaining the original angle. This method requires a steady hand and focus. Using a Dremel can be faster but demands precision. Have you considered the benefits of modern tools in sharpening? They often save time when used correctly.

Using A Dedicated Sharpener

For efficiency, a dedicated blade sharpener is unmatched. It’s a worthwhile investment if you frequently sharpen blades. These machines automate the process. They ensure consistent angles and uniform sharpness. Simply place the blade in the sharpener and let it work its magic. Dedicated sharpeners offer convenience but come with a cost. Is the ease of use worth the investment for your projects? It’s a decision many DIY enthusiasts face. Choosing the right sharpening technique can transform your woodworking experience. Each method has its own charm and challenges. Which one aligns with your style and needs?

Reinstalling The Blade

Reinstalling the blade is a critical step after sharpening. A well-sharpened blade performs best when correctly reinstalled. Proper installation ensures smooth operation and safety. Below are some steps to guide you through the process.

How To Align The Blade Properly

Ensure the saw is unplugged before starting. Position the blade on the saw’s arbor carefully. Align the blade so that the teeth face the correct direction. Check your saw’s manual for guidance.

Securing The Blade In Place

Once aligned, secure the blade using the arbor nut. Use a wrench to tighten the nut firmly. Ensure it is snug, but avoid over-tightening. This prevents damage to the blade and saw.

Testing The Blade Installation

Plug the saw back in and test it briefly. Listen for any unusual sounds. If everything sounds normal, the blade is installed correctly. If not, turn off the saw and recheck the installation.

Safety Precautions To Consider

Always wear protective gloves during installation. They prevent cuts from sharp edges. Also, ensure you wear safety goggles to protect your eyes.

Testing The Blade

Testing the blade is crucial after sharpening. It ensures that your circular saw cuts accurately and efficiently. A well-sharpened blade not only improves performance but also extends its lifespan. Proper testing can save time and enhance safety during use.

Check For Smooth Cuts

Start by cutting a piece of wood. Observe the cut closely. A sharp blade should glide through the material smoothly. If you notice any rough edges or resistance, further sharpening may be needed.

Examine The Blade Teeth

Inspect each tooth of the blade. They should have a consistent sharpness. Uneven edges or dull spots can affect the quality of the cut. A magnifying glass can help with a detailed inspection.

Test Cutting Speed

Measure the speed of the cut. A sharp blade will cut faster and with less effort. Slow cutting may indicate a need for more sharpening or adjustment. Use a stopwatch for accuracy.

Listen For Unusual Sounds

Pay attention to any unusual noises during cutting. A properly sharpened blade should run quietly. Grinding or squealing sounds could suggest improper sharpening or alignment issues.

Assess The Blade’s Vibration

Feel for vibrations while cutting. Excessive vibration indicates problems with the blade’s balance. A balanced blade should operate smoothly without shaking or jittering.

Maintenance Tips

Sharpening a circular saw blade extends its life and improves cutting efficiency. Use a diamond blade sharpener for precise results. Secure the saw blade, gently grinding each tooth evenly. Regular maintenance ensures smoother cuts and longer-lasting tools.

Maintaining your circular saw blade is crucial for ensuring smooth and efficient cuts. Regular maintenance not only extends the life of your blade but also enhances safety while using it. Let’s dive into some practical tips that will keep your saw blade in top-notch condition.

Inspect Regularly

Make it a habit to inspect your circular saw blade for any signs of damage or wear. Look for chipped teeth or any warping. A damaged blade can lead to inaccurate cuts and potential hazards. By catching issues early, you can prevent bigger problems down the line.

Clean Thoroughly

After every few uses, give your blade a thorough cleaning. Dust and debris can accumulate and affect performance. Use a brush to remove sawdust and a mild solvent to wipe away resin buildup. A clean blade cuts more effectively and smoothly.

Proper Storage

Store your saw blades in a dry and safe location. Moisture can cause rust, which compromises the blade’s integrity. Consider using blade sleeves or cases to protect them from physical damage. Proper storage ensures your blades remain sharp and ready for use. Sharpening your blade can seem daunting, but it’s manageable with the right approach. You could use a diamond file or a dedicated blade sharpener. Follow the tooth’s angle and be consistent with pressure. A sharper blade means precise cuts and less strain on your saw.

Safety First

When handling your blade for maintenance, prioritize safety. Wear gloves to protect your hands from sharp edges. Ensure your saw is unplugged and stable before removing the blade. Safety precautions prevent accidents and keep you confident during maintenance. Have you ever noticed how a freshly sharpened blade transforms the way you work? The ease and precision can be incredibly satisfying. By adopting these tips, you can maintain that sharpness and efficiency every time you use your saw.

Credit: smallboatsmonthly.com

Frequently Asked Questions

What Is The Best Way To Sharpen A Circular Saw Blade?

Use a diamond file or specialized sharpening tool for precision. Secure the blade, mark the starting point, and file each tooth evenly. Ensure consistent pressure and maintain the original angle. Regular maintenance extends blade life and improves cutting efficiency. Always prioritize safety by wearing protective gear while sharpening.

How Much Does It Cost To Get A Circular Saw Blade Sharpened?

Sharpening a circular saw blade costs between $15 to $25 per blade. Prices vary by service provider and blade size. Contact local sharpening services for exact quotes. Regular maintenance extends blade life and improves cutting efficiency. Consider professional sharpening for precision and safety.

Does Ace Hardware Sharpen Saw Blades?

Ace Hardware stores often offer saw blade sharpening services. Availability can vary by location, so contact your local store for details. Professional sharpening can extend blade life and improve cutting performance. Ensure your saw blades are in good condition to achieve optimal results.

Is It Better To Sharpen Saw Blades Or Buy New?

Sharpening saw blades is often more cost-effective than buying new ones. It extends the blade’s lifespan and maintains cutting efficiency. Only replace if the blade is damaged or excessively worn. Regular sharpening ensures optimal performance and saves money in the long run.

Conclusion

Sharpening a circular saw blade requires patience and care. Regular maintenance keeps the blade efficient. Safety is important, so wear gloves and goggles. Use a diamond file or sharpening tool. Ensure even sharpening on each tooth. Check the blade’s condition frequently.

Replace if too damaged. A sharp blade cuts smoothly and saves time. Always follow the manufacturer’s guidelines. Proper sharpening extends the blade’s life. Your saw performs better with a sharp blade. Practice makes perfect, so don’t rush the process. Keep learning and improving your technique.

A well-maintained blade benefits your projects greatly.