Ever wondered what a soldering iron is used for? If you’re curious about this handy tool, you’re in the right place.

Imagine having the power to mend, create, and transform objects with just a bit of heat and precision. Whether you’re a DIY enthusiast, a budding electronics hobbyist, or someone who loves crafting, understanding the purpose of a soldering iron can open up a world of possibilities for you.

It’s not just about connecting wires; it’s about unlocking creativity and achieving perfection in your projects. You might be surprised at how versatile this tool can be and how it can become your new favorite gadget. Stay with us, and you’ll soon discover the magic behind the soldering iron and how it can revolutionize your workbench.

Basics Of Soldering Irons

If you’ve ever wondered how tiny electronic components stick together to form complex circuits, you’re not alone. This magic often begins with a soldering iron—a tool that is as essential to electronics as a paintbrush is to art. Whether you’re a hobbyist or a budding engineer, understanding the basics of soldering irons can open up a world of possibilities. The right soldering iron can help you repair gadgets, create custom projects, and even learn the fundamentals of electronics.

Types Of Soldering Irons

When it comes to choosing a soldering iron, you’ll find several types that cater to different needs. Basic soldering ironsare perfect for beginners; they are simple, plug-and-play tools that heat up quickly. If you’re into more advanced tasks, soldering stationsoffer adjustable temperatures, making them versatile for various materials. Then there are cordless soldering irons, ideal for on-the-go repairs and outdoor projects. Each type has its unique advantages, so consider what you’ll be using it for before making a purchase.

Key Components

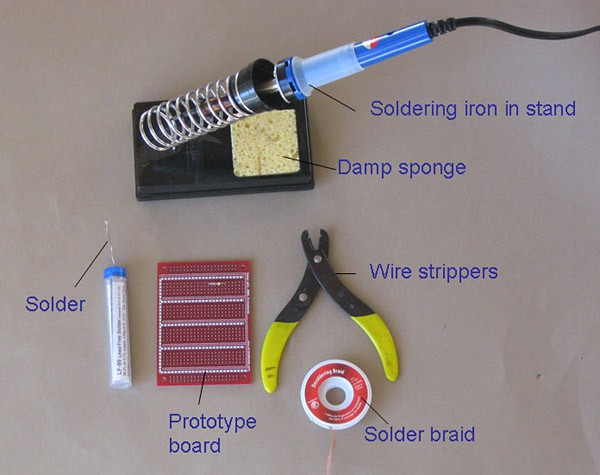

A soldering iron has several essential components that work together to make soldering possible. The heating elementis crucial; it heats the tip to melt solder, allowing it to flow and bond materials. The tipitself comes in various shapes and sizes, each suited for different tasks, from fine electronics to larger metal pieces. Don’t overlook the handle; a comfortable grip can make all the difference during prolonged use. Some models even include temperature control, offering precision in your work. Understanding these components will help you get the most out of your soldering iron.

Ever tried fixing a broken wire with just tape? It rarely works. Soldering irons offer a more reliable solution by creating strong, conductive joints. Imagine the satisfaction of repairing your own electronics rather than tossing them away. It’s not just about saving money; it’s about gaining the skills to tackle more complex projects. What could you create if you mastered the basics of soldering irons?

Credit: www.sciencebuddies.org

Essential Soldering Techniques

Soldering is a fundamental skill in electronics. It connects components securely. Mastering essential techniques is crucial for achieving strong, reliable joints. Understanding these techniques enhances your soldering skills. It also ensures long-lasting connections. Let’s explore some essential soldering techniques.

Tinning The Tip

Tinning involves coating the soldering iron tip with a thin layer of solder. This helps in conducting heat effectively. Start by heating the soldering iron. Clean the tip using a damp sponge. Apply solder to the tip once heated. Rotate the iron to cover the entire tip. Tinning ensures efficient heat transfer during soldering.

Making The Perfect Joint

Creating a perfect joint requires precision and patience. Begin by cleaning the components and the surfaces. Heat both the component and the solder pad. Apply solder to the joint. Let it flow and cover the area evenly. Avoid moving the components until the solder cools. A good joint looks shiny and smooth.

Common Diy Applications

Soldering irons are essential tools for joining metal pieces together. They are commonly used in electronics to connect wires and components. This tool works by melting solder, creating secure connections on circuit boards or repairing broken wires.

If you’re a DIY enthusiast, a soldering iron might just be your best friend. Whether you’re fixing up old gadgets, creating beautiful crafts, or working on intricate stained glass projects, this tool is indispensable. The versatility of a soldering iron opens up a world of possibilities for those who love to tinker and create.

Electronics Repair

Soldering irons are essential for anyone interested in electronics repair. They allow you to reconnect wires and fix broken circuits. Imagine reviving your old, cherished radio or repairing a frayed charging cable. The satisfaction of bringing electronics back to life is unmatched. Have you ever thought about fixing a loose wire in your headphones? With a soldering iron, you can easily mend it rather than buy a new pair. This not only saves money but also reduces electronic waste.

Craft And Jewelry Making

Crafting with a soldering iron opens up a world of creativity. Jewelry makers use it to join metals or attach decorative elements. You can design intricate patterns that are both beautiful and durable. Think about the joy of wearing a necklace you made yourself. A soldering iron helps you add personal touches that make your crafts truly unique. It’s a tool that transforms your creative ideas into tangible pieces of art.

Stained Glass Projects

Stained glass projects are another fascinating application for soldering irons. The tool helps you join pieces of glass with precision. This art form allows you to create stunning visual displays, perfect for windows or as standalone pieces. Have you ever admired the colorful glass windows in cathedrals? With patience and a soldering iron, you can craft your own miniature masterpiece. It’s a rewarding hobby that combines skill, creativity, and patience. In each of these applications, a soldering iron is more than just a tool. It’s a gateway to creativity and functionality. What project will you tackle next with your soldering iron? Let your imagination guide you.

Credit: www.aixuntech.com

Advanced Soldering Projects

Advanced soldering projects open a world of creativity. These projects go beyond basic repairs. They allow you to design unique items and gadgets. With skill and precision, you can transform simple materials into art and technology. Let’s explore some exciting advanced soldering projects.

Building Custom Circuit Boards

Custom circuit boards are the heart of electronic devices. With a soldering iron, you can design boards for specific functions. Start by arranging components like resistors and capacitors. Solder them onto a blank board carefully. This process demands precision and attention to detail. It improves your understanding of electronics. Custom circuit boards enable you to create tailored solutions. They are essential for hobbyists and professionals alike.

Creating Metal Sculptures

Metal sculptures offer a unique artistic expression. Using a soldering iron, artists can join metal pieces seamlessly. This technique requires patience and creativity. Sculptures can range from small figurines to large installations. Soldering allows for intricate designs and sturdy structures. It transforms simple metal into stunning works of art. This project is perfect for those who love both art and engineering. Metal sculptures showcase the beauty of form and function combined.

Safety Precautions

Soldering irons are essential tools for electronics projects and repairs. Knowing how to use them safely is crucial. This ensures your safety and the longevity of your equipment. Understanding safety precautions helps prevent accidents and injuries.

Handling Tips

Always unplug the soldering iron when not in use. This prevents accidental burns or fires. Never touch the metal tip directly. It can reach temperatures over 400 degrees Celsius. Use a stand to hold the iron when it’s hot. This keeps the work area safe. Work in a well-ventilated space. This prevents inhaling harmful fumes. Avoid using the iron near flammable materials.

Protective Gear

Wear heat-resistant gloves to protect your hands. Safety goggles are essential to shield your eyes from splashes. Long sleeves help guard your arms against accidental burns. Consider using a respirator mask if fumes are strong. Keep a fire extinguisher nearby. This is vital for emergencies. Ensure your workspace has good lighting. It helps you see clearly and work safely.

Maintenance And Care

Soldering irons are essential tools for electronics work. Proper maintenance and care extend their life. Good practices ensure safe and efficient soldering. Learn how to maintain your soldering iron below.

Cleaning The Tip

The tip of a soldering iron must stay clean. A dirty tip affects the quality of your work. Wipe the tip with a damp sponge after use. This removes solder residue and other debris. For stubborn grime, use a brass wire cleaner. This helps maintain the tip’s heat conductivity.

Use a tip tinner to restore the tip’s condition. Apply it while the tip is hot. This process helps prevent oxidation. Oxidation reduces the tip’s effectiveness. Regular cleaning makes soldering smooth and precise.

Storage Solutions

Proper storage keeps your soldering iron in good shape. Store it in a cool, dry place. Moisture can damage the iron over time. Use a stand or holder for safe storage. This prevents accidental burns or damage.

Unplug the soldering iron after use. Let it cool before storing. This prevents overheating and prolongs its life. Regular maintenance and care ensure your soldering iron performs well. Keep it clean and store it properly for best results.

Choosing The Right Soldering Iron

Picking the perfect soldering iron can feel overwhelming. Different tasks require different tools. It’s essential to know what you need. This guide will help you make the right choice.

Considerations For Beginners

Starting with soldering? A basic iron is often best. Look for a model that’s easy to use. Adjustable temperature can be helpful. A lightweight design aids precision. Safety features are also crucial. Beginners should feel comfortable and safe.

Features For Professionals

Professionals need more advanced tools. Temperature control is key. Some tasks require specific heat settings. Look for a soldering iron with rapid heating. Interchangeable tips offer versatility. Durability is important for frequent use. A reliable tool ensures consistent results.

Troubleshooting Common Issues

Soldering irons are essential tools for electronic repairs and projects. They join metal components by melting solder. Sometimes, issues arise during soldering, affecting the quality of your work. Knowing common problems helps in achieving better results. Here, we address frequent soldering challenges.

Cold Joints

Cold joints occur when the solder doesn’t melt properly. This results in weak connections. They may look dull and brittle. Check the temperature setting on your soldering iron. It should be hot enough to melt solder smoothly. Clean the iron tip regularly for efficient heat transfer. Use fresh solder to improve joint quality.

Overheating Problems

Overheating can damage components and ruin connections. It happens if the iron is too hot or used for too long. Monitor your soldering iron’s temperature settings. Use a heat-resistant mat to protect delicate parts. Work quickly and efficiently to avoid prolonged heat exposure. Let the iron cool between uses.

Credit: www.dandelions.cloud

Frequently Asked Questions

What Is A Soldering Iron Used For?

A soldering iron is used to join metal pieces together. It melts solder, a metal alloy, to create strong, conductive connections. Commonly used in electronics, it repairs circuit boards and wires. It’s essential for hobbies like model building and jewelry making, offering precision and control.

How Does A Soldering Iron Work?

A soldering iron works by heating up to melt solder. The heated tip liquefies the solder, which then flows onto the metals. As the solder cools, it solidifies, creating a bond between the surfaces. This process ensures electrical conductivity and mechanical stability.

Can Soldering Irons Be Used For Jewelry?

Yes, soldering irons can be used for jewelry making. They help connect metal pieces with precision. The iron’s heat is suitable for soldering small components. It’s ideal for creating intricate designs and repairing broken jewelry. Proper technique ensures clean and secure connections.

Why Is Soldering Important In Electronics?

Soldering is crucial in electronics for connecting components securely. It ensures stable electrical connections within circuit boards. Reliable solder joints prevent circuit failures and improve device performance. Soldering allows for repairs and modifications, extending the lifespan of electronic gadgets.

Conclusion

A soldering iron is a handy tool for many projects. It helps join metal parts by melting solder. People use it in electronics, plumbing, and jewelry making. It’s great for fixing broken wires and creating connections. Beginners and experts both find it useful.

Choose the right soldering iron for your needs. Practice makes perfect, so start with simple tasks. Remember to work safely. Keep your workspace clean and organized. Always turn off the soldering iron after use. With time, you’ll gain confidence and skill.

Enjoy your soldering projects and the satisfaction they bring!